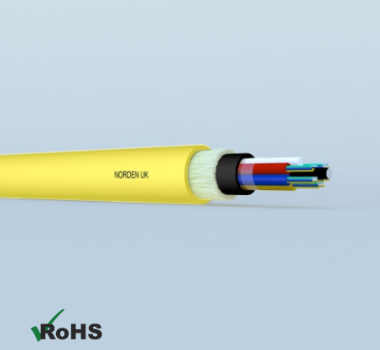

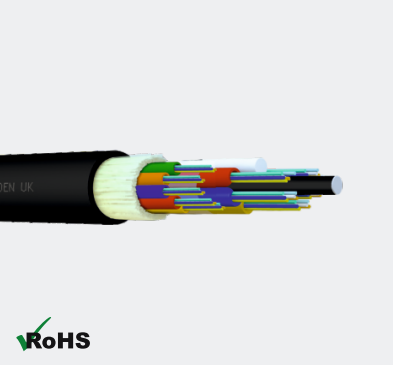

These cables are constructed with multiple tubes filled with water-blocking jelly. They form the backbone of high-speed networks and give flexibility to networks. Non-metallic FRP & Aramid Yarn strength members in the cable give it good tensile strength, water blocking jelly in the tube and tape over the tube give it excellent water and moisture resistance. Double-sided PE sheath cable gives more excellent tensile strength, and mechanical, rodent, ultraviolet, and environmental protection. This cable is suitable for internal, external, and long-distance communication systems.

These cables are constructed with multiple tubes filled with

water-blocking jelly. They form the backbone of high-speed

networks and give flexibility to networks. Non-metallic FRP &

Aramid Yarn strength members in the cable give it good tensile

strength, water blocking jelly in the tube and tape over the tube

give it excellent water and moisture resistance. Double-sided PE

sheath cable gives more excellent tensile strength, and

mechanical, rodent, ultraviolet, and environmental protection.

This cable is suitable for internal, external, and long-distance

communication systems.

| Characteristics | Short Term |

Max. Crush Load | 2200 N /10 cm |

Max. Tensile Load | 2700N/10cm |

Operating Temp. | -5 °C to +70 °C |

Storage Temp. | -5 °C to +70 °C |

Sheath Material | HDPE |

| Part Number | Fibre Count | Outer Diameter (mm) | Cable Weight (kg/km) | Bend Radius | |

| Short (mm) | Long (mm) | ||||

| 4026-H1024FXXCL | 24 | 12.0 | 125 | 20D | 10D |

| 4026-H1072FXXCL | 72 | 12.0 | 125 | 20D | 10D |

| 4026-H1096FXXCL | 96 | 13.6 | 160 | 20D | 10D |

| 4026-H1144FXXCL | 144 | 16.0 | 190 | 20D | 10D |