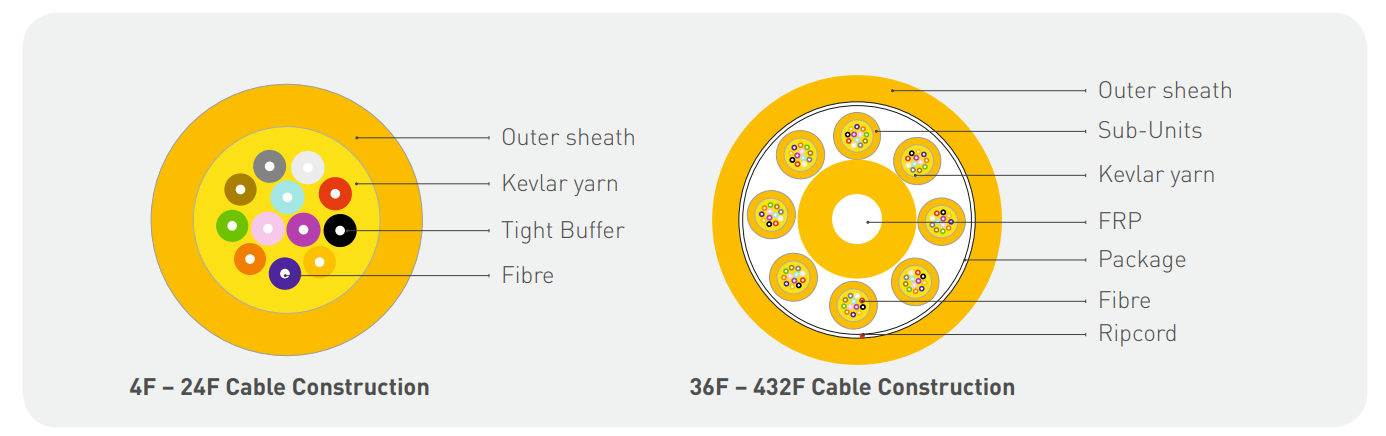

Norden Pre- Terminated Break Out patch cord comprises tight buffer fibre housed within a common outer jacket in OM1, OM2, OM3, OM4, OS1, OS2 multi-mode and single mode variants. Both ends are terminated with a high-performance hybrid or single type connector consisting of a SC, ST, FC, LC, MTRJ, E2000 connector in simplex and duplex. Using pre-terminated patch cords can simplify the installation process and reduce the need for on-site termination, making them a convenient choice for various networking applications.

Norden Pre- Terminated Break Out patch cord comprises tight buffer fibre housed within a common outer jacket in OM1, OM2, OM3, OM4, OS1, OS2 multi-mode and single mode variants. Both ends are terminated with a high-performance hybrid or single type connector consisting of a SC, ST, FC, LC, MTRJ, E2000 connector in simplex and duplex. Using pre-terminated patch cords can simplify the installation process and reduce the need for on-site termination, making them a convenient choice for various networking applications.

Telcordia (formerly Bellcore) GR-326-CORE Generic requirements for Single mode optical connectors and Jumper

assemblies.

IEC 874-1 Generic specification for fibre optic connectors and cables

ANSI/TIA-568-C.3, ISO/IEC 11801 2nd Ed., CENELEC EN 50173, UL94V-0

ST, SC, FC, LC, MT-RJ, E2000 connectors

Position A/Position B markings

100% factory transmission tested per ANSI/TIA-568-C.3

Slim-profile boots with durable flexible cable strain relief

|

Range of Mode |

Single or Multimode |

|

Connector Style |

SC, FC, ST, LC, MTRJ, E2000 |

|

Polish or Ferrule Interface Type |

PC, UPC, APC |

|

Lengths |

Standard & Custom Lengths |

|

Strength Member |

Kevlar Yarn |

|

Cable Assembly Length (<15 meter Tolerance) |

-0/+100mm |

|

Cable Assembly Length (>15 meter Tolerance) |

-0/+10% |

|

Durability |

500 cycles(0.2 dB max increase), 1000mate/demate cycles |

|

Installation Temperature range |

-10°C to +60°C |

|

Operation and transport temperature | -20°C to +75°C |

|

Ferrule Concentricity |

< 1μm, Other Ferrule Concentricity < 1μm |

|

Humidity (FOTP-5) |

90-95% at 40°C |

|

Strength of Coupling Mechanism (FOTP-185) |

33 N at 0° for 5 sec |

|

Cable Retention (FOTP-6) |

50 N at 0° for 5 sec. |

|

Twist (FOTP-36) |

15 N at 0° 5 turns, 10 cycles |

|

Flex (FOTP-1) |

0.5 Kg at 25 cm, +90° to -90°, 100 cycles |

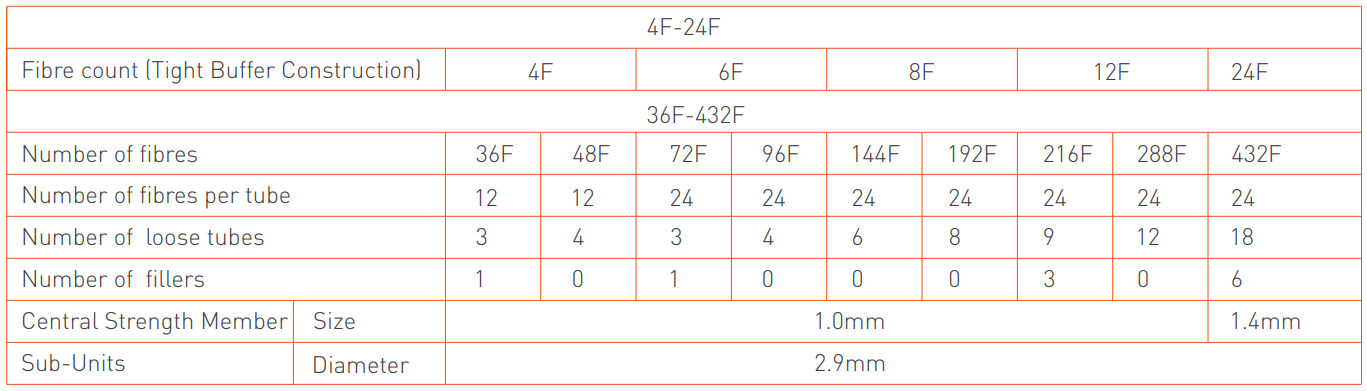

| Central Strength Member Material | FRP |

| Subunit Material | LSZH |

|

Item |

Single mode |

Multimode |

||||

|

PC |

UPC |

APC |

62.5/125 |

50/125 |

50/125 10G |

|

|

Insert. Loss/connector (single Fibre) |

0.2dB Max. (0.15dB typ.) |

0.3dB Max. (0.25dB typ.) |

||||

|

Return Loss |

≥ 45 dB |

≥ 50 dB |

≥ 60 dB |

N.A |

||

|

Insert. Loss/MTRJ Connector |

0.5dB Max. (0.45dB typ.) |

0.5dB Max. (0.45dB typ.) |

||||

|

Pull strength |

≥98N |

≥98N |

≥98N |

≥98N |

||

| Geometric Specifications | |

|

Radius of Curvature |

7-25 mm |

|

Apex Offset |

0-50 um |

|

Radial Fibre Height -50 |

-50 to +50 nm |

|

Angular Offset |

<0.3 degrees |

|

Fibre Roughness |

0-25 nm |

|

Ferrule Roughness |

0-50 nm |

| End Face Defects | |

|

Fibre Core |

0 nm² |

|

Mode field diameter |

0 nm² |

|

Ferrule contact zone |

0 nm² |

|

Testing & Inspection |

100% |

| Epoxy | |

|

Temperature Coeff .Tg |

120 |

|

Curing Method |

Out Gassed |

|

Residual Epoxy |

No Visible Epoxy Ring |

| Configuration Control | |

|

Serialization |

Each Cable is Serialized |