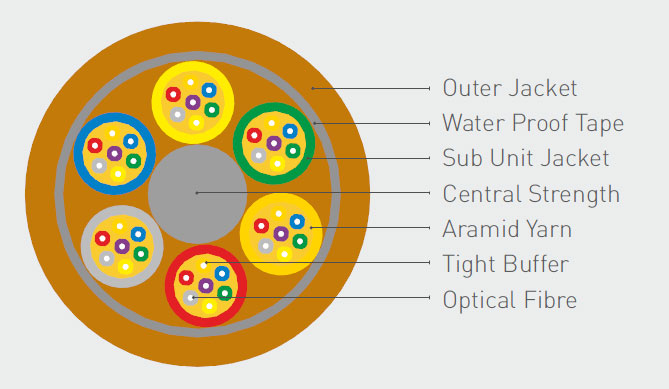

This high fibre count cable is formed from sub unit containing water blocking Aramid and 12 fibres. These sub units are helically stranded to get cable sizes from 12 to 144 fibres. Tight buffer multi fibre cable design allows sub bundles to be routed to separate areas needing different fibre counts. These cables are used as internal distribution cables due to ease of their termination and connection. The installer can recognize saving from lower cost of termination of Tight buffer cables. They have high moisture resistance and can be routed across multiple bends. Each fibre is mechanically reinforced with two successive sheaths of 400μm and 900μm which enables direct termination of connectors. Excellent strip force stability, fibre geometrical dimension and transmission performance meets the customer demand. Available in PVC, LSZH, Plenum outer sheath and tight buffer: 900μm, 600μm. The cable is specially designed for internal applications like floor distribution, interconnection and equipment connection.

This high fibre count cable is formed from sub unit containing water blocking Aramid and 12 fibres. These sub units are helically stranded to get cable sizes from 12 to 144 fibres. Tight buffer multi fibre cable design allows sub bundles to be routed to separate areas needing different fibre counts. These cables are used as internal distribution cables due to ease of their termination and connection. The installer can recognize saving from lower cost of termination of Tight buffer cables. They have high moisture resistance and can be routed across multiple bends. Each fibre is mechanically reinforced with two successive sheaths of 400μm and 900μm which enables direct termination of connectors. Excellent strip force stability, fibre geometrical dimension and transmission performance meets the customer demand. Available in PVC, LSZH, Plenum outer sheath and tight buffer: 900μm, 600μm. The cable is specially designed for internal applications like floor distribution, interconnection and equipment connection.

|

COMPLIANCEITU-T G652.B OS1 |

| Characteristics | Short Term | Long Term | ||

|

Max. Tensile Load |

1500 N (for 12- 144 Core) | 800 N (for 196 Core) |

500 N (for 12- 144 Core) | 400 N (for 196 Core) |

|

Max. Crush Load |

1500 N/100 mm (for 12- 144 Core) | 600 N/100 mm

(for 196 Core) |

1000 N/100 mm (for 12- 144 Core | 300 N/100 mm

(for 196 Core) |

|

UL Fire Rated |

OFNR |

|||

|

Operating Temp. |

-20 °C to +60 °C |

|||

|

Storage Temp. |

-40 °C to +85 °C |

|||

|

Sheath Material |

Standard: PVC Optional: LSZH, PE or other |

|||

| Part Number | Fibre Count | Outer Diameter (mm) |

Sub Unit Diameter (mm) | Tight Buffer Diameter (mm) | Cable Weight (kg/km) |

Bend Radius | |

| Short (mm) |

Long (mm) |

||||||

|

3104-11012FXXCL |

12 |

13.5 |

5.0 | 0.9 |

145.0 |

20D |

15D |

|

3104-11024FXXCL |

24 |

13.5 |

5.0 | 0.9 |

145.0 |

20D |

15D |

|

3104-11036FXXCL |

36 |

15.8 |

5.0 | 0.9 |

255.0 |

20D |

15D |

|

3104-11048FXXCL |

48 |

15.8 |

5.0 | 0.9 |

260.0 |

20D |

15D |

|

3104-11072FXXCL |

72 |

18.5 |

5.0 | 0.9 |

305.0 |

20D |

15D |

|

3104-11096FXXCL |

96 |

22.5 |

5.0 | 0.9 |

475.0 |

20D |

15D |

|

3104-11144FXXCL |

144 |

29.5 |

5.0 | 0.9 |

845.0 |

20D |

15D |

| 3104-11196FXXCL | 196 | 21.4± 0.5 | 5.0 ± 0.2 | 0.55 ± 0.05 | 312.5 | 20D | 15D |