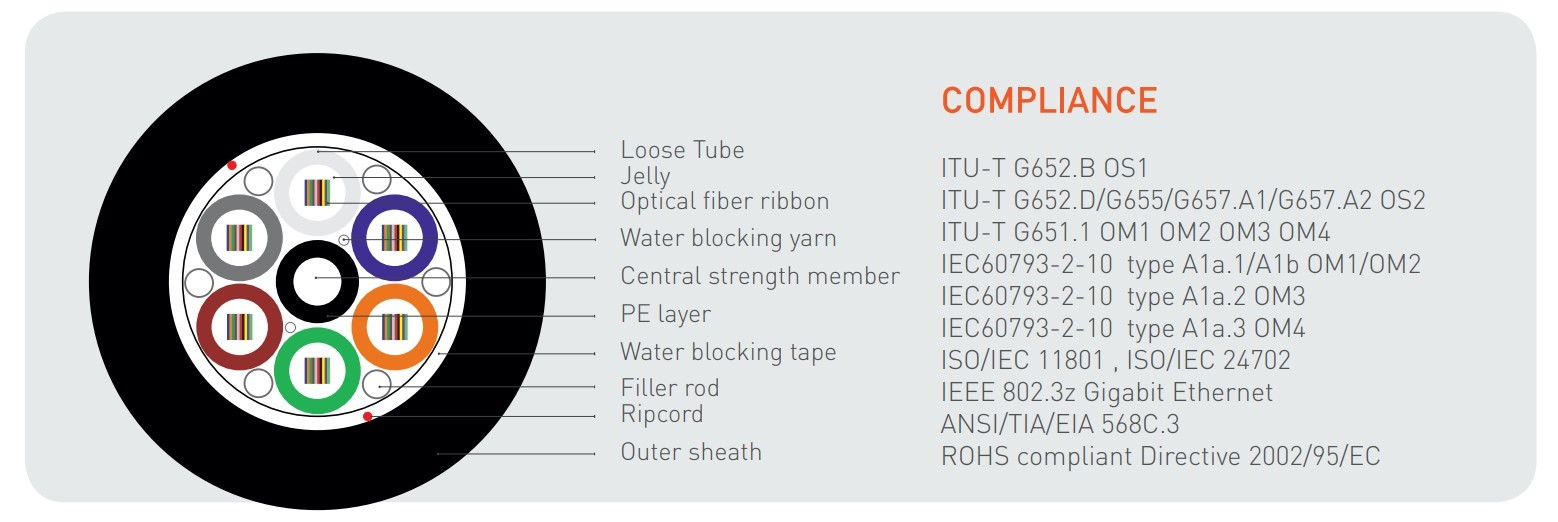

Norden Single Sheath Armoured Ribbon Optical Fibre Cable is engineered for underground duct, direct buried or aerial installation applications, incorporating a non-metallic, anti-buckling FRP rod as the central strength member for enhanced structural stability. It features loose buffer tubes filled with Thixotropic Jelly to safeguard the ribbon fibres, while the S-Z stranded core, wrapped with water-swellable tape, provides excellent moisture resistance. Additional reinforcement comes from a peripheral strength member made of glass yarn and corrugated ECCS tape, while the UV-stabilized HDPE outer sheath ensures durability in demanding environments. A rip cord enables easy sheath removal, and the flexible buffer tubes simplify fiber routing within closures. The cable is designed for superior mechanical protection, offering resistance to rodents, termites, salinity, and corrosion, ensuring long-term reliability in underground network installations.

Norden Single Sheath Armoured Ribbon Optical Fibre Cable is engineered for underground duct, direct buried or aerial installation applications, incorporating a non-metallic, anti-buckling FRP rod as the central strength member for enhanced structural stability. It features loose buffer tubes filled with Thixotropic Jelly to safeguard the ribbon fibres, while the S-Z stranded core, wrapped with water-swellable tape, provides excellent moisture resistance. Additional reinforcement comes from a peripheral strength member made of glass yarn and corrugated ECCS tape, while the UV-stabilized HDPE outer sheath ensures durability in demanding environments. A rip cord enables easy sheath removal, and the flexible buffer tubes simplify fiber routing within closures. The cable is designed for superior mechanical protection, offering resistance to rodents, termites, salinity, and corrosion, ensuring long-term reliability in underground network installations.

| Characteristics | Value |

Max. Tensile Load (IEC 60794-1-21-E1) | 3000 N @ 0.25% Fiber Strain |

Max. Crush Load (IEC 60794-1-21-E3) | 2000 N / (100 X 100 mm) |

Impact Resistance (IEC 60794-1-21-E4) | Height 500 mm, Weight = 50 N,10 Impact at different locations |

| Torsion Resistance (IEC 60794-1-21-E7) | 10 Cycle (± 180°) 100 N, L= 2 Mtr |

Cable Bending (IEC 60794-1-21-E11) | 4 Turns , 10 Cycles , 20 X D |

| Water Penetration (IEC 60794-1-22-F5) | 1 Meter Water Head, 3 Meters Cable Sample, 24 Hours |

| Operating Temperature | -20 °C to +70 °C |

| Installation Temperature | -20°C to +70°C |

| Storage Temperature | -20°C to +70°C |

| Jacket Material | HDPE (UV Stabilized) |

| Jacket Thickness | Min. 1.8 mm |

| Part Number | Fibre Count | No. of Fibre / Ribbon | No. of Ribbon Tube | No. of Loose Tube | No. of Filler Tube | Outer Diameter | Cable Weight (kg/km) | Bend Radius | |

| Short (mm) | Long (mm) | ||||||||

| 40R1-H110487A1CL | 48 | 6 | 2 | 4 | 1 | 15.5 ± 1.0 | 205 | 20 x D | 10 x D |

| 40R1-H120967A1CL | 96 | 6 | 4 | 4 | 1 | 17.0 ± 1.0 | 250 | 20 x D | 10 x D |

| 40R1-H131447A1CL | 144 | 6 | 6 | 4 | 1 | 18.0 ± 1.0 | 280 ± 10% | 20 x D | 10 x D |

| 40R1-H132167A1CL | 216 | 6 | 6 | 6 | 0 | 19.5 ± 1.0 | 320 ± 10% | 20 x D | 10 x D |

| 40R1-H132887A1CL | 288 | 6 | 6 | 8 | 0 | 22.5 ± 1.0 | 410 ± 10% | 20 x D | 10 x D |